Blueprint reading for welders 9th edition pdf free – Blueprint Reading for Welders, 9th Edition PDF Free provides a comprehensive guide to the fundamental principles and advanced techniques of blueprint reading for welders. This essential resource equips readers with the knowledge and skills necessary to interpret and apply blueprints accurately, ensuring efficient and precise welding projects.

Through detailed explanations, real-world examples, and practical exercises, the book covers all aspects of blueprint reading for welders, from understanding basic symbols and conventions to interpreting complex isometric drawings and using computer-aided design (CAD) software.

Blueprint Reading Fundamentals for Welders

Blueprint reading is a fundamental skill for welders. It enables them to interpret engineering drawings and understand the specifications for welding projects. This knowledge is essential for producing high-quality welds that meet industry standards.

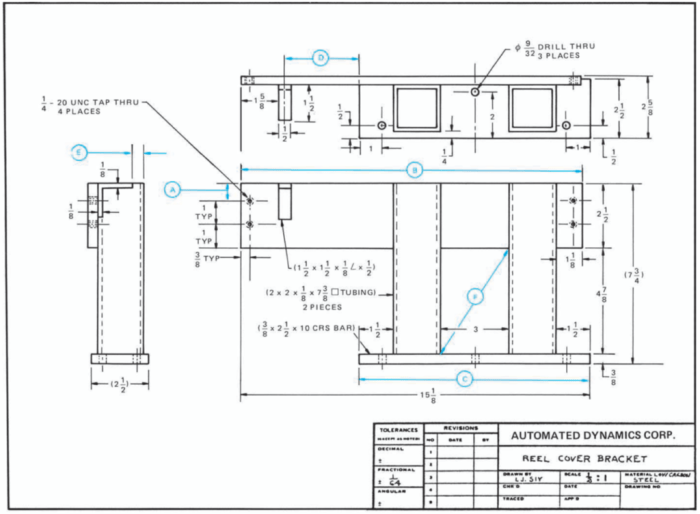

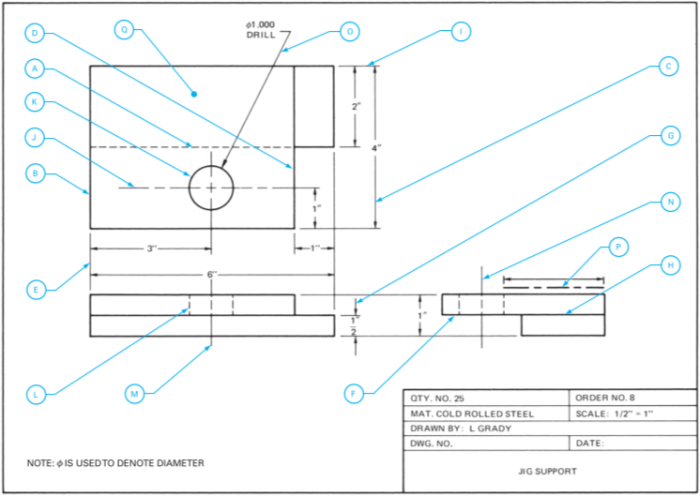

Different types of blueprints are used in welding, including orthographic projections, isometric drawings, and detail drawings. Each type of blueprint provides specific information about the welding project, such as the dimensions, materials, and welding processes required.

Basic Symbols and Conventions

Blueprint reading for welders requires familiarity with the basic symbols and conventions used in engineering drawings. These symbols represent different types of welds, dimensions, tolerances, and other annotations. By understanding these symbols, welders can accurately interpret blueprints and ensure that their welds meet the specified requirements.

Interpreting Welding Symbols

Types of Welds and Symbols

Welding symbols on blueprints provide detailed information about the type of weld required. These symbols include the weld type, weld size, and weld location. By understanding these symbols, welders can select the appropriate welding process and equipment for the job.

Weld Dimensions and Tolerances

Welding symbols also specify the dimensions and tolerances for the weld. These dimensions include the weld length, width, and depth. Tolerances indicate the acceptable range of variation for each dimension. By adhering to these dimensions and tolerances, welders can ensure the accuracy and quality of their welds.

Other Annotations, Blueprint reading for welders 9th edition pdf free

In addition to weld type, dimensions, and tolerances, welding symbols may also include other annotations. These annotations can provide additional information, such as the welding process to be used, the surface preparation required, and the inspection criteria.

Understanding Blueprint Dimensions

Measuring and Interpreting Dimensions

Blueprint dimensions provide the measurements for the welding project. These dimensions include the overall dimensions of the structure, as well as the dimensions of individual components. Welders must be able to accurately measure and interpret these dimensions to ensure that the welded structure meets the specified requirements.

Dimensioning Systems

Different dimensioning systems are used in welding blueprints, including the inch system and the metric system. Welders must be familiar with both systems to ensure accurate interpretation of blueprints.

Calculating and Verifying Dimensions

Welders may need to calculate and verify dimensions based on the information provided on the blueprint. This may involve using trigonometry or other mathematical calculations. By accurately calculating and verifying dimensions, welders can ensure that the welded structure meets the specified requirements.

Applying Blueprint Reading in Welding Projects: Blueprint Reading For Welders 9th Edition Pdf Free

Importance of Accurate Blueprint Interpretation

Accurate blueprint interpretation is essential for the success of welding projects. By understanding the blueprint specifications, welders can plan and execute their work efficiently and accurately. This can lead to improved welding quality, reduced rework, and increased productivity.

Planning and Executing Welding Tasks

Blueprint reading enables welders to plan and execute welding tasks effectively. They can determine the sequence of welding operations, select the appropriate welding equipment, and ensure that the welding process meets the specified requirements.

Improving Welding Efficiency and Accuracy

Proper blueprint interpretation can significantly improve welding efficiency and accuracy. By understanding the blueprint specifications, welders can avoid errors and rework, resulting in faster completion times and higher-quality welds.

Advanced Blueprint Reading Techniques

Interpreting Isometric Drawings

Isometric drawings provide a three-dimensional representation of the welding project. These drawings can be more difficult to interpret than orthographic projections, but they offer a more comprehensive view of the project.

Interpreting Specialized Blueprints

In addition to isometric drawings, welders may encounter other specialized blueprints, such as assembly drawings and fabrication drawings. These drawings provide detailed information about the assembly and fabrication of the welding project.

Using Computer-Aided Design (CAD) Software

Computer-aided design (CAD) software can be used to create and interpret blueprints. CAD software can provide welders with a digital representation of the welding project, which can be easily manipulated and modified.

Frequently Asked Questions

What is the importance of blueprint reading for welders?

Blueprint reading is essential for welders as it provides them with the detailed instructions and specifications necessary to accurately fabricate and assemble welded structures.

What types of blueprints are commonly used in welding?

Welders typically encounter various types of blueprints, including fabrication drawings, assembly drawings, and detail drawings.

How can welders interpret welding symbols on blueprints?

Welding symbols on blueprints convey specific information about the type of weld, its dimensions, and other relevant details. Welders must be familiar with these symbols to correctly interpret and execute welding tasks.